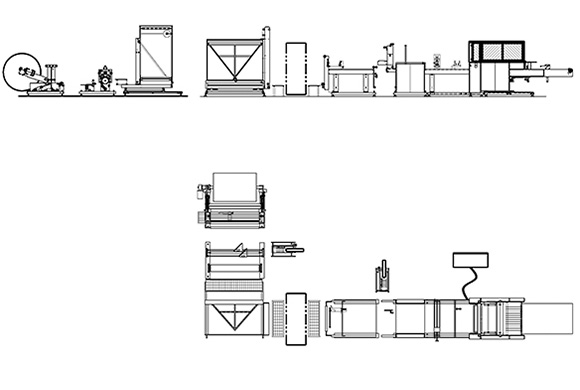

ETH 200

Saldatrice appositamente studiata per la produzione di tutte le tipologie di sacchi sicurezza con saldatura laterale doppia tipo shopper e saldatura larga tipo sottovuoto.

La macchina può lavorare materiali come LDPE – LLDPE – HDPE – COEX, ecc.

Innovazioni tecnologiche avanzate sono state applicate a questa nostra linea dedicata alla produzione di sacchi sicurezza in quanto, dall’utilizzo nel trasporto valori alla spedizione di documenti riservati, dall’uso da parte della polizia per conservare le prove ai duty-free per il trasporto di liquidi negli aerei, e comunque da tutti i settori nei quali è fondamentale una protezione contro la manipolazione degli oggetti contenuti nel sacchetto stesso, è emersa la necessità di sviluppare tecniche per la saldatura laterale tipo sottovuoto con larghezze fino a 15 mm per ogni lato del sacchetto, oltre all’applicazione di sistemi di identificazione e tracciabilità delle buste stesse.

Poiché questa tipologia di prodotto richiede spesso una grande quantità di applicazioni simultanee sullo stesso sacco, il lavoro dell’operatore viene complicato notevolmente andando ad incidere sulla produttività e sulla qualità del prodotto finito.

Grazie all’automatizzazione di tutta una serie di operazioni normalmente delegate appunto all’operatore, siamo in grado di offrire saldatrici con soluzioni “chiavi in mano” per la produzione di qualunque tipologia di sacco di sicurezza, permettendo così un incremento della produzione e della qualità del prodotto :

– tamper-evident semplicemente incollati oppure saldati sulla busta;

– profili di saldatura rettilinei oppure sagomati per rendere più difficile qualunque tentativo di manipolazione del sacco;

– integrazione nella macchina di codificatori di numeri seriali/codici a barre, sia a getto di inchiostro che a trasferimento termico;

– sistema di scanner per la verifica automatica della corrispondenza dei codici stampati sulle buste (talvolta fino a 4 su ogni sacchetto) e per il controllo di qualità;

– applicatori di RFID;

– unità di spalmatura colla con pompe ad ingranaggi;

– stampa automatica delle etichette da applicare sulle scatole di cartone, con le informazioni relative ai numeri sequenziali dei sacchi contenuti nell’imballo ed ai pezzi mancanti dovuti a scarti di produzione.

• Saldatura doppia, tipo shopper, con profili saldanti da 2 a 6 mm e distanza tra le due saldature da 5 a 14 mm..

• Saldatura larga sottovuoto con profilo saldante da 5 a 30 mm.

• Utilizzo di bobine di nastro sicurezza “VOID” già accoppiato con liner siliconato con hot-melt; questo nastro deve essere aperto e riaccoppiato dopo essere stato divaricato in modo da lasciare scoperta una parte adesiva che dovrà essere attaccata alla busta.

• Utilizzo di una bobina di nastro sicurezza “VOID” che dovrà essere spalmato con colla hot-melt ed accoppiato con un nastro siliconato lasciando una parte adesiva scoperta che dovrà essere attaccata alla busta (nel caso in cui il nastro di sicurezza sia in HDPE questo potrà essere saldato su la busta stessa e non incollato).

• Utilizzo di una bobina di nastro sicurezza “VOID” in HDPE che dovrà essere saldato su la busta ed un nastro siliconato spalmato di colla hot-melt che dovrà essere attaccata alla busta, dalla parte opposta del nastro di sicurezza.

• Fustelle per maniglie con taglio parziale o asportazione totale dello scarto e per foro europeo, con tagli a freddo (a denti o a matrice) e a caldo.

• Unità di saldatura ovale intorno alla maniglia.

• Presaldatori soffietti (pneumatici o servomotorizzati).

• Saldature longitudinali ad aria calda oppure a contatto.

• Svolgitori motorizzati per nastri biadesivi removibili o permanenti.

• Unità di pretaglio singole o doppie per ricevute.

• Unità di pretaglio trasversale per sacchi doppi.

• Accessori per saldatura larga sottovuoto (pneumatici o servomotorizzati).

• Piegatori pattelle.

• Tagli longitudinali intermittenti, a registro stampa.

• Accessori per spalmatura colla intermittente/continua di hot-melt.

• Applicatori di numeri seriali e codici a barre con getto di inchiostro o trasferimento termico.

• Applicatori etichette di carta ed RFID.

• Ponti perforatori.

- Larghezze disponibili

- Lunghezza minima dei sacchi

- Lunghezza massima dei sacchi

- Velocità meccanica

- Velocità scorrimento

80 mm

1000 mm

280 c./min (variabile in base al modello)

120 mt/min

Comments are closed.