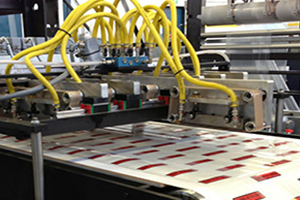

La SCAE Europe, con oltre 50 anni di esperienza nel campo delle saldatrici, continua a rivolgere tutte le risorse aziendali in un continuo progresso tecnologico per poter offrire alla propria clientela un prodotto al passo con i tempi e spesso all’avanguardia, utilizzando per la costruzione delle proprie macchine materiali e componentistica di alto standard qualitativo, per garantirne la maggior affidabilità, prestazione e durata.

Leggi altro..

Tutti i nuovi modelli di saldatrici della serie ETH utilizzano, oggi, il più moderno protocolloopen source Ethercat ad alte prestazioni, basato su Ethernet a 100 Mb, con vantaggi tecnologici quali trasmissioni dati su cavo digitale ad alta velocità ed alta risoluzione, performance indipendenti dalla quantità di dati con conseguente riduzione del tempo di ciclo ed ottimizzazione delle velocità di produzione, il poter organizzare ….

Leggi altro..

All'interno della nostra sezione è possibile richiedere la quotazione per i ricambi dei nostri macchinari. Inoltre è possibile conoscere la disponibilità dei nostri prodotti, i tempi di spedizione e i costi compilando il nostro modulo on line.

Nel minor tempo possibile vi invieremo la nostra migliore offerta con tutte le informazioni dettagliate richieste. Non esitate a contattarci per le vostre richieste.

Comments are closed.